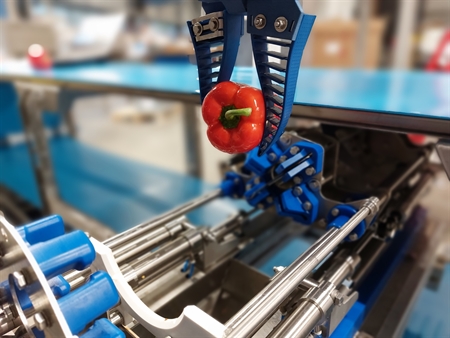

Vision technology, robotics, and deep learning are ensuring a fully autonomous bell pepper processing line.

In our new bell pepper line, you won't see any people," says Machiel Honig, co-owner of ZTI smart machines, a company specializing in developing machinery for the vegetable and fruit processing industry. "Tipping over crates of bell peppers is enough to eventually produce halves or quarters of peppers that are devoid of the core.

"In this new processing line, the bell peppers are examined with a camera and then picked up by the robot's silicone gripper. Thanks to this vision technology, the robot knows exactly how the pepper should be positioned for the core removal unit. This unit then precisely removes the heart of the pepper. After the core is removed, the pepper can be cut into two or four equal parts." Hans Keijzer, co-owner, emphasizes that the automation of the process prevents a lot of loss. "It cannot be expected of workers to consistently place peppers in the machine for hours. A robot makes no mistakes and never gets tired."

Repetitive Movements

In addition, this automated process results in significant labor savings, according to Machiel. He considers it one of the main drivers for automating bell pepper processing. The repetitive nature of the work also plays a role, says Hans. "If you have to make the same movement for hours on end, it's not the most pleasant work for long-term health."

Apart from labor savings—Hans sees the potential to save at least two workers—the sustainability component also plays a crucial role. "By collecting a lot of data about the peppers in this case, feedback can be given to the operator. If it turns out that this batch contains slightly smaller peppers, for example, a slightly smaller drill can be used so that more of the fruit is preserved."

More Possibilities

While the processing line was initially developed for bell peppers, Machiel sees plenty of other possibilities for processing other vegetables and fruits. "The technology we use here, a combination of vision technology, robotics, and deep learning, is not limited to bell peppers alone. Our machine can, in broad terms, be used for other products with various options."

The bell pepper line comes to the market as a modular package, Hans notes. He points out that, depending on the process, the required capacity, and the available space, a choice in components and the level of automation can be made. "In this decision, the option may be considered to still use some manual labor, which can then be automated later if desired. But no matter how the line is configured, there is an advantage to it."

Hygiene and Safety

The development phase considered energy consumption, Machiel explains. "It plays a role. We calculate energy consumption to an optimum, so no more is used than strictly necessary." Attention to hygiene has also been given since the concept phase. "We use the cleaning-in-place technique that can be applied during the process. We can temporarily let the robot work on another module." Because robots are used, less shielding is needed for safety, making the machine easier to clean. "There is a wide-open view of what is happening in the machine, which is an advantage for hygiene and maintenance," adds Hans.

The techniques used also contribute to the safety of the workers, notes Machiel. "With this processing line, it is easier to create distance between the knives and the people. With other machines, we find that the measures needed to create a safe workplace bring considerable costs. Now, using these robots, and with the process completed in a shielded space, we can more easily keep operators away from the knives, especially when the machine runs completely autonomously."