How the Destemmer came to life

A customer asked us whether we could develop a machine for destemming grapes. He had ten people lined up, standing by crates, manually turning the grapes from the bunches. A labour-intensive job. In addition, the repetitive twisting movement, which must be made from the wrist, could increase the risk of RSI. An automated solution was necessary. But not easy.

A few important principles

An important condition was that the grapes had to be turned from the stem, not pulled. When you pull the grape off, it damages the skin at the growing point of the grape. This immediately shortens the shelf life of the product. In addition, turning must be done with care, the fruit must not be bruised or crushed. Finally, the machine should be creating a decrease in the costs. A payback period of between one and one and a half years was desired.

Trial and error

We sat down at the drawing board with these principles. A few test setups were built from the first sketches. Including a bed with rotating silicone toadstools over which a truss could be towed. The grapes could be transported to the belt below in between the mushrooms. This worked, but just not good enough.

The customer showed us how to quickly destem a bunch of grapes. He made a kind of hand-rubbing motion around a bunch. Much of the grapes came loose with this motion! Test set-up two therefore became a new concept. We mounted inflated inner bicycle tubes on a rotating plate. That way we could imitate a rotating, hand-rubbing, movement. This result was reasonable. The problem was that the friction decreased due to condensation. This also reduced the effectiveness of the system.

What do you do against condensation? Hot air. At first, we heated the tires. But with heating alone, we did not achieve the desired result. The solution was to install a fan. This fan blew heated air over the grapes and drove off the moisture at the same time.

Combination of test setups lead to the desired result

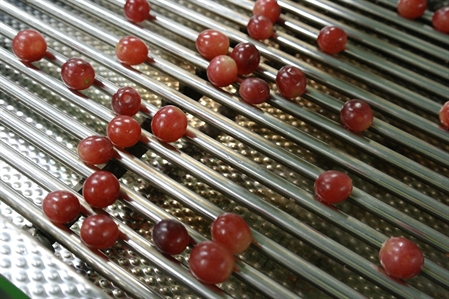

The current Destemmer was created by combining both test setups (the silicone mats, the blower and the rotating movement). A symmetrical system, made with two moving silicone pads arranged in a v-shape. The V-shape ensures that the grapes and stems can roll from the bottom of the machine onto a belt.

One Destemmer with three people on the line (for advancing the machine and reading the belt) has the same capacity as 10 people who manually turn the grapes.