Effortless destemming cherry tomatoes

Convenience fruit has been on the rise for a number of years now. Mixed fruit salads containing grapes are in great demand in supermarkets worldwide. It is not without reason that the Destemmer is one of our bestselling machines. So yes, now we know grape destemming is a piece of cake for the Destemmer, but cherry tomatoes are also processed with the same ease on this versatile machine.

Special processing due to rotating movement

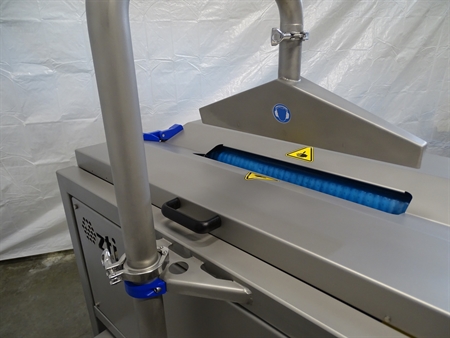

Machiel Honig, engineer and co-owner of ZTI, started designing the machine a few years ago. The starting point was to come to a design in which the machine rotates the fruits off the stem. Honig: "It is not difficult to come up with a machine that pulls or shakes the fruit from the stem. If you are going to pull or risk the fruits off a bunch, then you will indeed have quick results. But for longer shelf life it is important that the fruits are handled with the utmost care. Thanks to the silicone pads the fruit is literally turned off the stem. The growth point therefore remains intact and that ensures a longer shelf life. That is what we, and our customers, naturally aim for".

Cherry tomatoes can also be processed very well on the Destemmer

The manual picking of a bunch of cherry tomatoes is also not longer necessary. That can also easily be done by the Destemmer. The trusses are fed in at the top of the machine and the fruits are turned neatly and without damaging the stem. The soft "friction pads" in the machine ensure that the fruits do not get bruised. When the fruits are loose from the truss, they roll on the conveyor belt.

Capacity and employability

Depending on the type, the Destemmer processes up to approximately 500 kilograms per hour. Optionally, the machine can be equipped with supply and discharge conveyor belts, a dryer, a washer and a shaker. It is also possible to install a funnel or bunker above the Destemmer. This addition feeds the grapes gradually in the machine. A volume detection system automatically stops the conveyor when the bunker has reached its capacity.

The Destemmer is also being used to destem dates.

Video cherry tomatoes