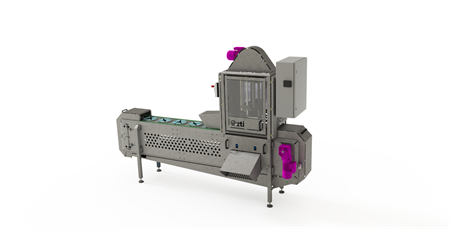

Fruit & Vegetable Wedger

The Fruit & Vegetable Wedger is suitable for wedging all kinds of fruit and vegetables. For example, bell pepper, celeriac, cabbage and pumpkin and different species of fruit like melon, pineapple and apple. The product is cut into two halves, or four or five wedges. The machine processes maximal thirty pieces per minute. The cutting result gives you sharp and even wedges, ready to be packed or to be further processed.

Very safe and easy to operate

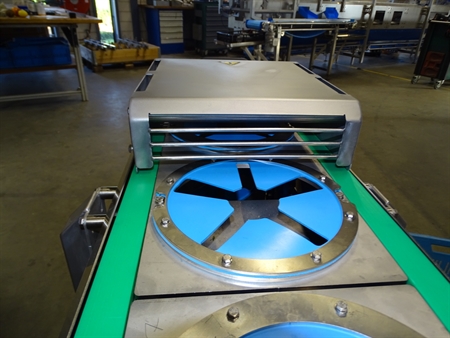

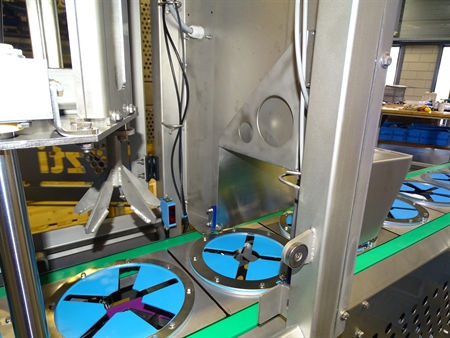

The products are manually placed into the rubber holders on the belt. Once placed in the trays, the chain transport moves it into the machine. Whilst the fruit or vegetable is entering the cutting area, there is no possibility to come in contact with the knives. The cutting area is a closed compartment that can only be opened when the machine is not operating.

Different options available

The standard version is equipped with trays for four and for five wedges. This makes it possible to cut smaller wedges from a big celeriac for example. Naturally this can be adjusted to your wishes. In the guarded cutting area, a knife is pushed through the product from below. A holder above keeps the product in place for nice and even wedges. The blades can be found right under the trays in the guarded area and can easily be taken out through an outlet at the side of the machine. As an option the 4 and 5 segmented blades can be exchanged by two 1 segmented blades cutting the product in two halves.

The wedges are guided out of the machine through a gutter at the side of the machine. There they can be collected in a receptacle or moved upwards by a conveyor. If desired a counter can be mounted to tell you exactly how many cutting movements have been made.

Features of our fruit and vegetable processing machines

- Careful treatment and processing improve the shelf life

- High processing capacity

- Maximum yield per processed product

- Equals or betters manual processing

- Visually attractive end product

- Meet European guidelines for the food-processing industry in relation to hygiene and safety

Features of all ZTI smart machines - Smart innovations that are distinguished by their simplicity

- Simple and safe to operate

- Easy to clean and to service

- Equipped with the latest technology

- Optimum balance between 'mechanics' and 'electronics'

- Attractive return on investment